- Mon-Fri: 8:00am - 6:00pm

- 41-04 35th Avenue, Long Island City, N.Y. 11101

A power plant contractor was hampered by a narrow corridor adjacent to a facility in which to locate temporary containment for contaminated water during boiler cleanout.

Meeting an urgent delivery deadline, ModuTank Inc. provided two rental EconoTanks with a combined capacity of 324,000 gallons for rapid installation conforming to the site’s dimensions. A similar cleanout project met requirements with custom designed, narrow and long half-million and million gallon EconoTanks.

An existing greenhouse was the proposed site for raising exotic fish.

Two Modutanks, sized to fit the long narrow space, connected by a lengthwise integral inspection walkway and fitted with field coated seamless liners, were installed and ready to go in less than a week.

A superfund site required 600,000 gallons of effluent and 300,000 gallons of clean water storage on an irregularly shaped site.Necessary capacity was supplied by three 15 ’high round Modustor tanks designed to fit the available area and installed on weatherresistant,steel alloy footing plate systems thereby avoiding any penetration or alteration of the site.

A similar space problem affected an indoor installation on a floor crowded with process equipment.Storage and handling for 145,000 gallons of dredged effluent were successfully managed by three 20 ’high and one 15 ’high, free-standing,interconnected ModuStor tanks.

A demonstration project for an innovative wastewater treatment process required two 800-ft. chlorine contact tanks, each handling a flow rate of one-million gallons per day. Linear tanks would be unacceptably long and less convenient to monitor.

A similar space problem affected an indoor installation on a floor crowded with process equipment.Storage and handling for 145,000 gallons of dredged effluent were successfully managed by three 20 ’high and one 15 ’high, free-standing,interconnected ModuStor tanks.

A process for safely transforming municipal sewage sludge into organic fertilizer depended on durable, long-lived holding tanks. Equally important were cost-effectiveness, fast shipment, and quick and easy field assembly.

During a three-phase, four-year program, the municipality installed three ModuTanks: one with 500,000 gallon capacity and two with 2,000,000 gallon capacity each. Both larger tanks were priced at less than 12¢ per gallon, and each were up and functional in under two weeks.

A power plant contractor was hampered by a narrow corridor adjacent to a facility in which to locate temporary containment for contaminated water during boiler cleanout.

Meeting an urgent delivery deadline, ModuTank Inc. provided two rental EconoTanks with a combined capacity of 324,000 gallons for rapid installation conforming to the site’s dimensions. A similar cleanout project met requirements with custom designed, narrow and long half-million and million gallon EconoTanks.

An existing greenhouse was the proposed site for raising exotic fish.

Two Modutanks, sized to fit the long narrow space, connected by a lengthwise integral inspection walkway and fitted with field coated seamless liners, were installed and ready to go in less than a week.

A superfund site required 600,000 gallons of effluent and 300,000 gallons of clean water storage on an irregularly shaped site.Necessary capacity was supplied by three 15 ’high round Modustor tanks designed to fit the available area and installed on weatherresistant,steel alloy footing plate systems thereby avoiding any penetration or alteration of the site.

A similar space problem affected an indoor installation on a floor crowded with process equipment.Storage and handling for 145,000 gallons of dredged effluent were successfully managed by three 20 ’high and one 15 ’high, free-standing,interconnected ModuStor tanks.

A Durable one-piece collapsible tanks for liquid storage offer low-cost solutions for special requirements such as these:

• Extensive maintenance within a water system at a national park involved storage of potable during repair work. A 50,000-gallon bladder tank was supplied for temporary use, and then repacked for standby storage.

• A construction crew in a remote mountainous site immediately required a source of potable water for the duration of their project. A 50,000-gallon bladder tank was delivered via expedited shipping in time for the job to proceed.

• A 20,000-gallon capacity bladder tank was supplied for use in a narrow mine tunnel to store runoff water.

• Power plant construction required 1,500,000 gallon storage of cooling tower water. To meet this need the initial 500,000 gallon EconoTank shipped the day after receipt of order; the follow-on 1,000,000 gallon EconoTank shipped one day later. The 500,000 gallon and 1,000,000 gallon EconoTank were installed and ready for use 8 days after the shipment.

• Military base remediation project called for holding 6,000,000 gallons of contaminated ground water prior to discharge. Two 1,000,000 gallon EconoTanks shipped two days after the receipt of order. Balance of four 1,000,000 gallon EconoTanks shipped weekly thereafter in accordance with project schedule. Client’s eight man work crew sequentially installed the EconoTanks in four days per tank.

• Refinery startup required 3,000,000 gallon effluent storage in order to meet contract requirements. Two 1,500,000 gallon EconoTanks were installed and on-line two weeks after receipt of order.

Sludge from a coal liquification project contained in a claylined pond was leaking hydrocarbons into a waterway and was threatening the local ground water supply. A serious environmental hazard existed.

The company’s contractor recommended and specified two ModuTanks, with a total capacity of 330,000 gallons, for temporary storage of sludge during site remediation. Although the original plan was to scrap the tanks after they had served their purpose, the plan was changed. Impressed with the Modutank’s functional advantages and speed of installation, the utility assigned the contractor to disassemble the units, clean their oil-resistant flexible membrane liners, and warehouse them for future applications.

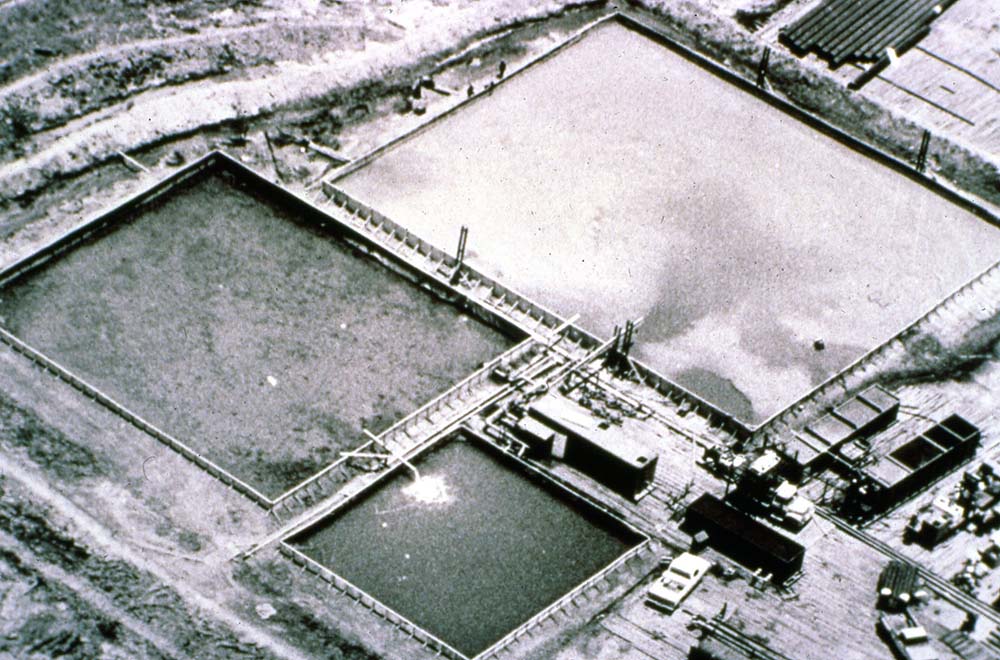

A Superfund project required long term storage of 600,000 gallons of effluent and 300,000 gallons of clean water. Due to regulatory and contractual requirements, no permanent alteration of the irregularly shaped and severely constricted site was permitted.

Necessary capacity was supplied by three 15′ high round ModuStor tanks designed to fit the available area and installed on weather- resistant, steel alloy footing plate systems (patent pending) therby avoiding any alteration or penetration of the site.

A government agency required a 500,000 gallon hazardous waste water storage tank for a Massachusetts Superfund site. Concurrently a 300,000 gallon ModuTank purchased previously by the same agency was no longer needed at a Superfund in Ohio.

The 300,000 gallon ModuTank was dismantled and shipped to the new site. Additional Modutank components were supplied and the tank reconfigured to the 500,000 capacity for use and subsequent relocation to a third site.

Spent de-icing fluid flushed over aircraft at a major international airport posed a pollution hazard. A means of collection, storage and disposal was urgently required.

A series of low-cost ModuTanks, with 1.2 million gallons in total capacity, was strategically stationed to safely contain the fluid. The first four of the facilities were shipped within 72 hours of the order and delivered to the site 24 hours later. Owing to their modularity, the Modutanks were conveniently disassembled and later transported to other locales at the airport for similar service.

Oil spillage into a local river was subjecting a New York State company to steep environmental penalties of $70,000. A proposed oil/water separation system was required by a narrow site between a building and roadway. Speedy resolution of the situation was essential.

The company’s consulting engineer phoned on Friday, requesting a budget price for a customized 34,500 gallon ModuTank with a fitted, reinforced, oil-resistant flexible membrane liner with integral baffles. The tank was ordered on Monday, shipped Wednesday, received the next day, and fully installed in eight hours by five workmen with simple hand tools. By Saturday, the 19′ x 53′ ModuTank was fully operational in a tight location on a site requiring minimum preparation.

An economical means of providing reusable, relocatable, easily assembled hazardous waste holding tanks was sought by a major waste treatment company.

Fifteen ModuTanks, each having a capacity of 50,000 gallons were supplied to the company’s various branch locations. These were then deployed as needed and subsequently relocated to other sites as required, thereby providing logistic flexibility.

200,000 gallons of storage were urgently needed for a Southern California facility project.

Two 100,000 gallon EconoTanks were ordered at 9 A.M. Parts were fabricated and shipped via airfreight from New York that evening and delivered to the site at 2 P.M. the following day. Both tanks were assembled and ready for use 12 hours later.

Earthquake zones pose substantial hazards to containment systems which, accordingly, must be engineered and rebuilt to withstand the shock and stress of earth tremors. Such installations required tanks designed and manufactured to rigid Seismic 4 specifications.

Meeting or exceeding all Seismic 4 requirements, more than 20 tanks in capacities from 30,000 to 1,100,000 gallons have been supplied. Our reliable, heavy-duty facilities are today in service in California, Utah, Washington, Texas and Colorado.

Two existing 15,000 gallon chemical storage tanks were mounted in tandem on concrete saddles over exposed ground. Immediately safeguarding the neighboring area against spillage from possible tank ruptures was the customer’s preemptive concern.

After a thorough study of the tank’s footing arrangements, a customized ModuTank with 25,000 gallon capacity was installed. Without disturbing the 25-ft. long tank’s positions or operation, the ModuTank’s protective liner was precision-cut on site, then fitted and attached around the saddles with watertight seals.

Providing temporary leachate collection from land fills during treatmentplant construction was a priority need. Supplying such facilities rapidly and at relatively low cost was equally critical.

Retained by a consulting company on behalf of two of its clients, ModuTank Inc. quickly manufactured and shipped the specified tanks: two 250,000 gallon facilities to each of two different locations. All four tanks were furnished with double liners with leak detection and floating covers.

A municipal landfill required additional permanent leachate collection capacity of 4,000,000 gallons. Time and budget restraints were important.

Two 2,000,000 gallon Hi-Stor tanks with double liners, leak detection and floating covers were installed on a fast track under budget basis.

Large storms predicted for the fast-approaching stormy season could cause a possible overflow from a large hazardous waste storage pond.

In less than 48 hours after receiving this rental order, a 1,000,000 gallon EconoTank was in shipment to the customer. Assembled near the waste storage pond to which it is linked by a pumping system, the facility secures the site by providing temporary containment for potential spillover.

A salt mine chamber was excavated 2,500 feet below ground level to receive storage facilities for fuel oil and hydraulic fluid. The confined space was 8-ft. high and accessible only by a conventional shaft elevator.

The easily hand-carried galvanized steel components of two 10,000 gallon VariTanks with covers were conveniently transported to their deep site through the mine’s elevator and tunnel.

• Astrophysicists tracking neutrinos at the U.S. South Pole Research Station needed to place detectors at the bottom of 6,500 foot deep holes drilled in the ice. They required a holding tank capable of withstanding extreme sub-zero cold while holding hot drilling water. Furthermore, the tank had to be shipped in compact, knock-down form because of limited cargo space. The solution was a specially lined, modular tank erected on site which held heated drilling water during its successful operation.

• Government and university hydrologists required a method to simulate forest streams storm conditions for studying flood control and environmental protection methods. The answer was a low-cost, short term rental of an “L” shaped 33,000 gallon modular tank configured to emulate storm water channel flow patterns.

• An international testing laboratory required immersion testing of large industrial components in order to provide the laboratory’s seal of approval. Although the test space available was limited and constricted, a rectangular 10,600 gallon modular tank was installed to provide the necessary volume and depth.

An overseas U.S. government facility required secure underground fuel storage for its building’s energy systems, in a region subject to severe earthquakes.

Modular components for two LiquiGard tanks, custom fit with bladders totaling 80,500 gallons in capacity, were hand-carried and rapidly assembled in a specially designed vault below the building. Both tanks offered secondary containment, leak detection, and were built to withstand the increase in seismic requirements.